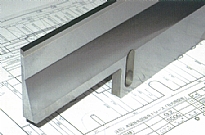

Solid Non-joint Blade

Do you have troubles in precision of works ?

Then let’s try the non-joint centerless blade of TTN Tateno.

WHY NON-JOINT?

Because of non-joint, work pieces run very smoothly. Thus, remarkably reduce scratches on work pieces. Blade surface is very strong against original wear because of mirror finish. Maximum length of 1,500mm blade can be manufactured as non-joint piece. As for the grade of tungsten carbide, we accept any grade at customer’s request.